Guardian Insulation Solutions

Duo Cavity Sock - 91-100mm Cavity x 1.2m - 3 Hour Fire Rating

Duo Cavity Sock - 91-100mm Cavity x 1.2m - 3 Hour Fire Rating

Couldn't load pickup availability

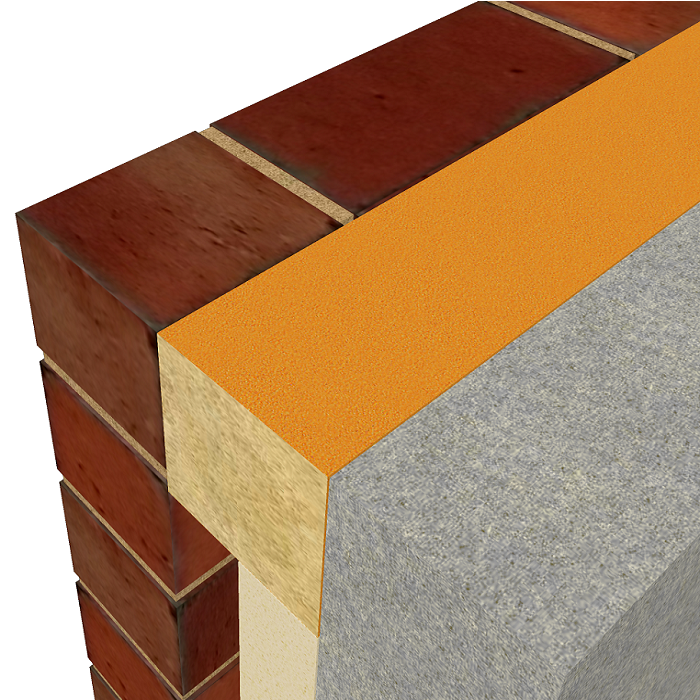

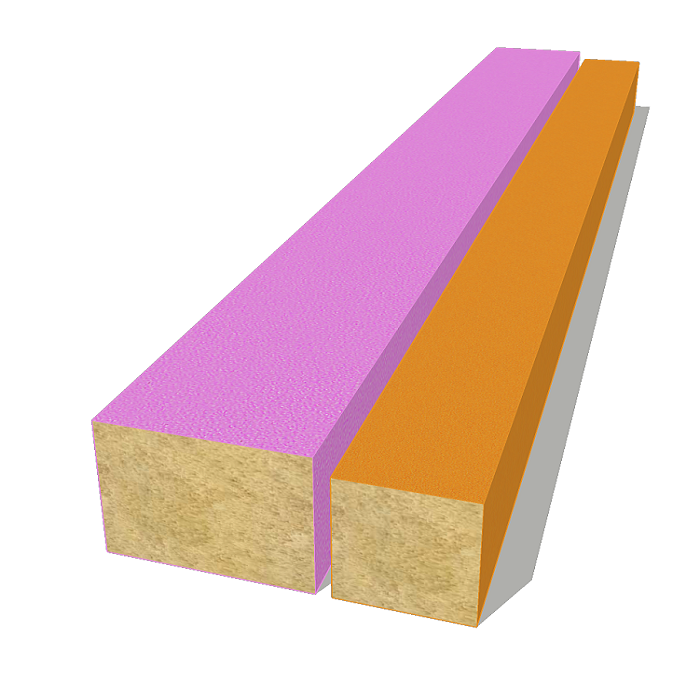

GIS Duo Cavity Socks are designed to suit both Masonry/Blockwork & Masonry/Timber frame/rated MF systems in construction applications. GIS Duo Cavity Socks are designed to prevent the spread of flames and smoke as well as reducing the spread of sound along the cavity. GIS Duo Cavity Socks are designed to meet current fire and building regulations and are rigorously tested to current accreditation and provides up to 4 hours fire integrity. GIS Duo Cavity Socks are 1200mm long and are manufactured from Knauf ECOSE Mineral Wool and are encapsulated in recycled plastic.

FIRE

GIS Duo Cavity Socks are manufactured using Knauf ECOSE Rock Slab which has a fire classification of EUROCLASS A1 tested to BSEN13501-1 which is encapsulated in recycled plastic which will not add to the propagation of a fire. All GIS Cavity Duo Socks are tested in application to BSEN1366-4 as was BS476: Part 20/22 using current fire test methods and meets part B of the building regulations. Tested for cavities up to 300mm wide both Vertical & Horizontal uses test report BMT/FE/IF/15078 if fitted between 2 substrates of equal or higher fire rating than Duosocks

ACOUSTICS

GIS Duo Cavity Socks meet the generic requirements for the prevention of flanking noise transmission, along external and separating wall cavities.

Meeting approved document E (2014)of the building regulations, for England, Wales & Ireland . (based on width range for application 65mm/75mm/85mm/90mm100mm/200mm/250mm/300mm or 450mm wide GIS Duo Cavity Socks have a thermal conductivity of 0.037W/mK and when fitted will provide an effective perimeter edge seal as stated in building regulations L1A and L2A as well as meeting section 6 of the Scottish building standards.

COMPLIANCE

GIS Duo Cavity Socks when correctly fitted meet the requirements laid out in part E of robust detail. For masonry in a separating wall/party wall, E-WM 1-21 is met. For Timber Frame in a separating wall/party wall E-WT 1-4 is met in a separating floor application E-FT 1-6 is met and for concrete in separating floor applications E-FC 1-14 is achieved.

Share